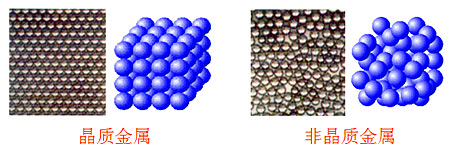

Amorphous materials and magnetic core introduction 一. The concept of amorphous alloys:Generally, for metals materials,the metals and alloys solidify from the liquid into a solid, the atoms always arrange neatly to be crystal which is crystalline metal.But if the metals or the alloys solidify so fast that it’s too late for the atoms to arrange neatly before they are frozen.Finally ,the atoms arrange disordered the same as when they are liquid,which is the amorphous alloy.

Amorphous alloy whose English name is AMORPHOUS is a new type of metal material.

Amorphous which is the invention of the 1960s and 1970s has a about 50 years’ history and particularly rapid development over the past decade. The differences between crystalline metal and amorphous metal: crystalline metal:Slow cooling at room temperature, atoms are arranged in neat rows .The short and long range are in order;

amorphous meta:Rapid cooling (about 1 / 106 sec), atoms are arranged irregularly. The short and long range are disordered.

Types of amorphous materials:After years of development ,there are many types of amorphous materials.Now we focus on two of them which are our current mass production.

1. Fe-based ultracrystalline(Nanocrystalline) 1K107

Main ingredients:Fe, Si, Nb, B, Cu

It is first made into amorphous material, and then forms a mixture of microcrystalline and amorphous organization after the proper anneal.This material is cheaper, but almost as excellent as cobalt-based amorphous alloys in the magnetic properties. It’s the ideal material of high-frequency transformer, transformer, inductor for industry and civil use as well as the replacement of the permalloy and ferrite as a kind of the amorphous materials which is most widely used at present. Applications:

can replace silicon steel, permalloy and ferrite, as various forms of high-frequency

• (20kHz-100kHz) The big,medium and small power of the main transformer, control transformer, filter inductor, inductor, choke, magnetic amplifiers, saturable reactor core, EMC filter inductor common mode and differential mode inductance core, ISDN miniature isolation transformer core in the switching power supply ; also widely used in all types of different precision of the transformer core . Characteristics of performance:

High saturation induction density, high permeability, low coercivity, low loss and good stability, wear resistance, corrosion resistance, also has a lower price,in all of the metal soft magnetic materials has the best price-performance 2. Fe-based amorphous 1K101

Main ingredients :Fe, Si, B

It is characterized by strong magnetic and soft magnetic properties are superior to silicon, cheap, also the ideal replacement of silicon.It is used for the low-frequency transformer core, such as distribution transformers, IF transformers, power inductors, reactors and so on. Applications:

• Midfrequency power transformer core:

• Be used as the core of ring without incision in switching power supply filtering outputting inductor, differential-mode inputting inductor

Be used as the noise suppression for car audio, core without incision of car guided systems choke ring

Be used as the core annular incision of air-conditioning, plasma TV in the power factor correction PFC

• Be used as the high-frequency rectangular cutting core of switching power supplies,uninterruptible power supplies and other high-frequency transformer

• Be used as the core ring without incision of IGBTs, MOSFETs, and GTOs pulse transformer

• Be used as stator and turn of high power density variable speed electric motor, generator Characteristics of performance :

1.the amorphous alloy has the highest saturation induction density - reduce the size of the device

2.Low coercivity - to improve the efficiency of the device

3. Low iron loss -to reduce the temperature of the device

4.Variable permeability - to meet different application requirements through different heat treatment processes to the core

5. Good stability - can work long at 130 ℃ |